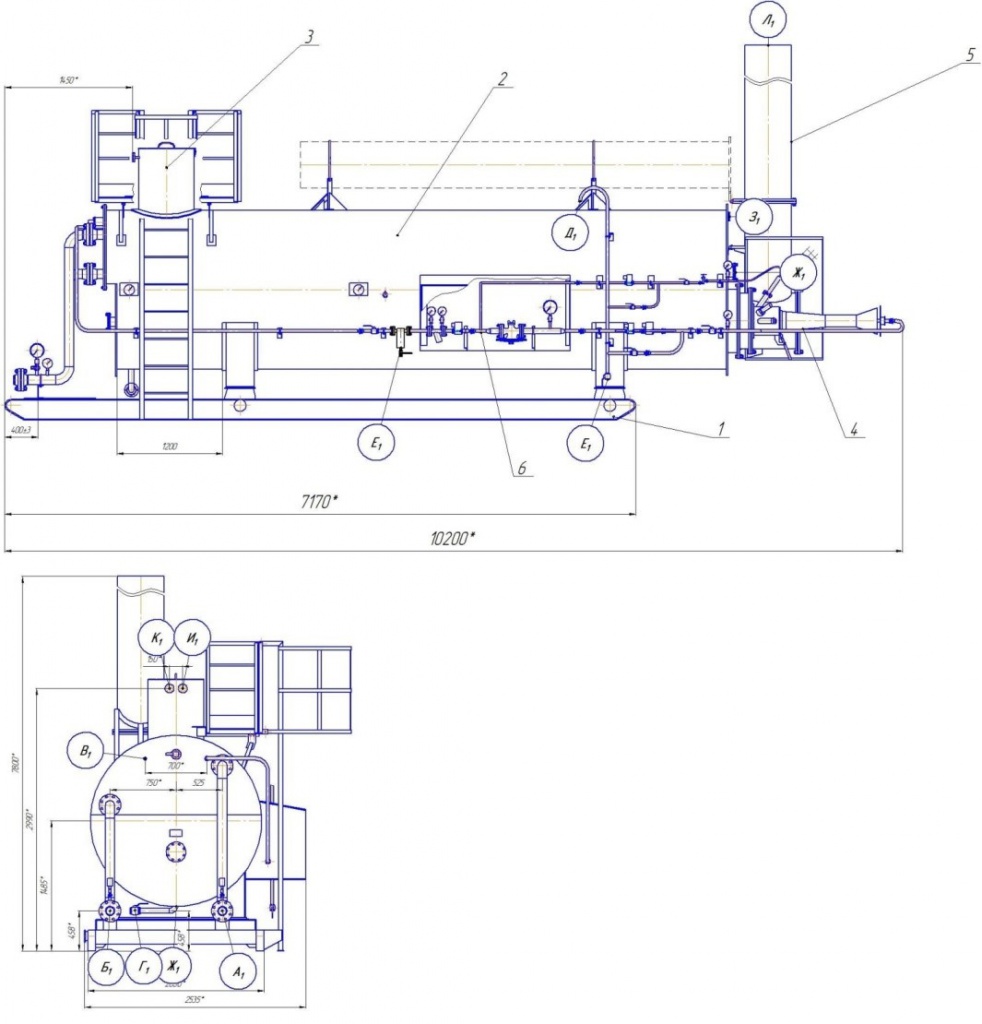

PP-0.63A general layout.

GENERAL DATA

Heaters intended for heating of oil products as well as oil emulsions at transporting and oil treating facilities.

features

Climatic modification – U, HLby GOST 15150-69.

Placement category–1 by GOST15150-69.

Common specifications

|

Parameter |

Value |

|||

|

PP-0.63А |

PP-0.63АZh |

PP-0.63AMZhG |

PP-0.63AS |

|

|

Rated heat capacity, MW (Gcal/hr) |

0.73 (0.63) |

|||

|

Heated product related productivity, t/day: - oil emulsion, water content 30% mass, at t =25°С |

1150 |

|||

|

Product temperature, °С: - at heater input, min - product output - intermediate carrier heating |

+5 +70 +95 |

|||

|

Efficiency factor, %, max |

80 |

|||

|

Intermediate heat carrier |

Sweet water, ethylene glycol solution, other inflammable heat carriers |

|||

|

Product coil pressure, MPa (kgf/cm2) : - working, max - estimated - hydro tested |

6.3 (63) 6.3 (63) 8.2 (82) |

|||

|

Heated medium parameters: - title - density at 20°С, kg/m3, max - viscosity at 20°С, cSt - hydrogen sulphide content (H2S), % mol., max - carbon dioxide content (СО2), % mol., max |

oil, oilemulsion 900 100 0.01 1.0 |

|||

|

Fuel parameters (natural or associated oil gas): - hydrogen sulphide content (H2S) , mass fraction, % max - combustion heat, MJ/m3, within - pressure at fuel treating unit input, MPa (kgf/cm2) within - pressure before burner, MPa (kgf/cm2) within

- fuel gas consumption, m3/hr, max |

0.002 35…60 0.2…0.4 (2.0…4.0) 0.07…0.15 (0.7…1.5) 100 |

- |

0.002 35…60 0.2…0.4 (2.0…4.0) 0.03 (0.3) 100 |

5 35…60 0.2…0.4 (2.0…4.0) 0.07…0.15 (0.7…1.5) 100 |

|

Fuel parameters (diesel fuel or oil): - lower combustion heat, kcal/kg - hydrogen sulphide content (H2S), mass fraction, % max - pressure before nozzle, MPa (kgf/cm2), max - fuel oil consumption, kg/hr, within |

- |

6800

0.002 4.0(40.0) 50…100 |

- |

|

|

Mass, kg, max: - without intermediate heat carrier. |

13000 |

13000 |

13880 |

13000 |

|

Service life, years, min |

10 |

|||

|

Reliability parameters: - average trouble-free life, years, min |

3.5 |

|||

PP-0.63A basic assembly units:

1) skid frame;

2) furnace shell;

3) expansion tank;

4) burner device;

5) fume stack;

6) fuel treating block

|

Chokes and Flanges Table |

||||

|

Ref |

Designation |

Qty |

Nominal |

DN, mm |

|

A1 |

Oil inlet |

1 |

6.3 (63) |

100 |

|

Б1 |

Oil outlet |

1 |

6.3 (63) |

100 |

|

В1 |

Fuel gas inlet |

1 |

1.6 (16) |

25 |

|

Г1 |

Tank drainage |

1 |

1.6 (16) |

50 |

|

Д1 |

Fuel gas purge to candle |

1 |

1.6 (16) |

25 |

|

Е1 |

Drainage of fuel gas lines |

2 |

1.6 (16) |

25 |

|

Ж1 |

Assembly choke |

3 |

0.1 (1.0) |

100 |

|

З1 |

Observation choke |

1 |

0.1 (1.0) |

80 |

|

И1 |

Heat carrier supply |

1 |

1 (10) |

20 |

|

К1 |

Heat carrier excess discharge |

1 |

1 (10) |

20 |

|

Л1 |

Fume gas outlet |

1 |

0.1 (1.0) |

500 |

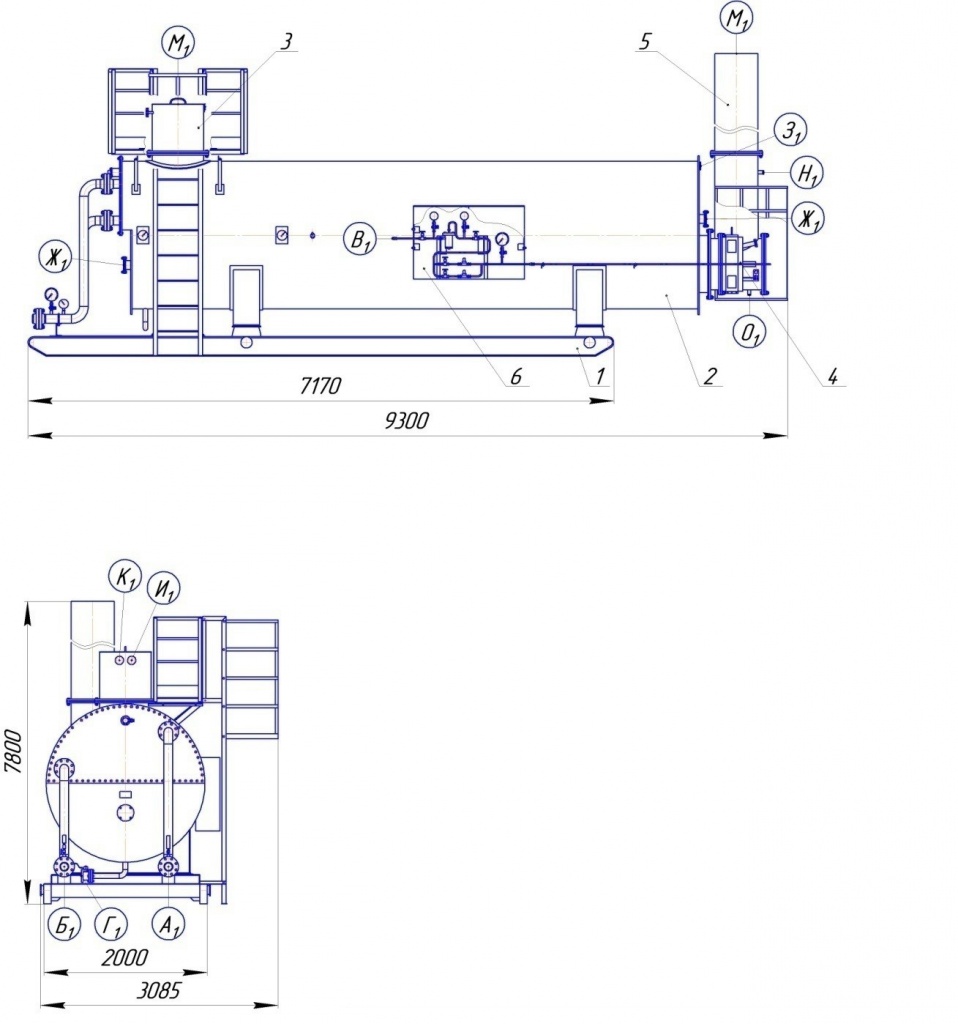

1) skid frame;

2) furnace shell;

3) expansion tank;

4) burner device;

5) fume stack;

6) fuel treating block

PP-0.63АZh general drawing.

|

Chokes and Flanges Table |

||||

|

Ref |

Designation |

Qty |

Nominal |

DN, mm |

|

A1 |

Oil inlet |

1 |

6.3 (63) |

100 |

|

Б1 |

Oil outlet |

1 |

6.3 (63) |

100 |

|

В1 |

Fuel gas inlet |

1 |

1.6 (16) |

25 |

|

Г1 |

Tank drainage |

1 |

1.6 (16) |

50 |

|

Ж1 |

Assembly choke |

1 |

0.1 (1.0) |

100 |

|

З1 |

Observation choke |

1 |

0.1 (1.0) |

80 |

|

Н1 |

Heat carrier supply |

1 |

1 (10) |

20 |

|

К1 |

Heat carrier discharge |

1 |

1 (10) |

20 |

|

М1 |

Fume gas outlet |

1 |

0.1 (1.0) |

500 |

|

Н1 |

Sampling choke with gas analyzer |

1 |

0.1 (1.0) |

20 |

|

О1 |

Drainage of furnace condensate |

1 |

0.1 (1.0) |

15 |

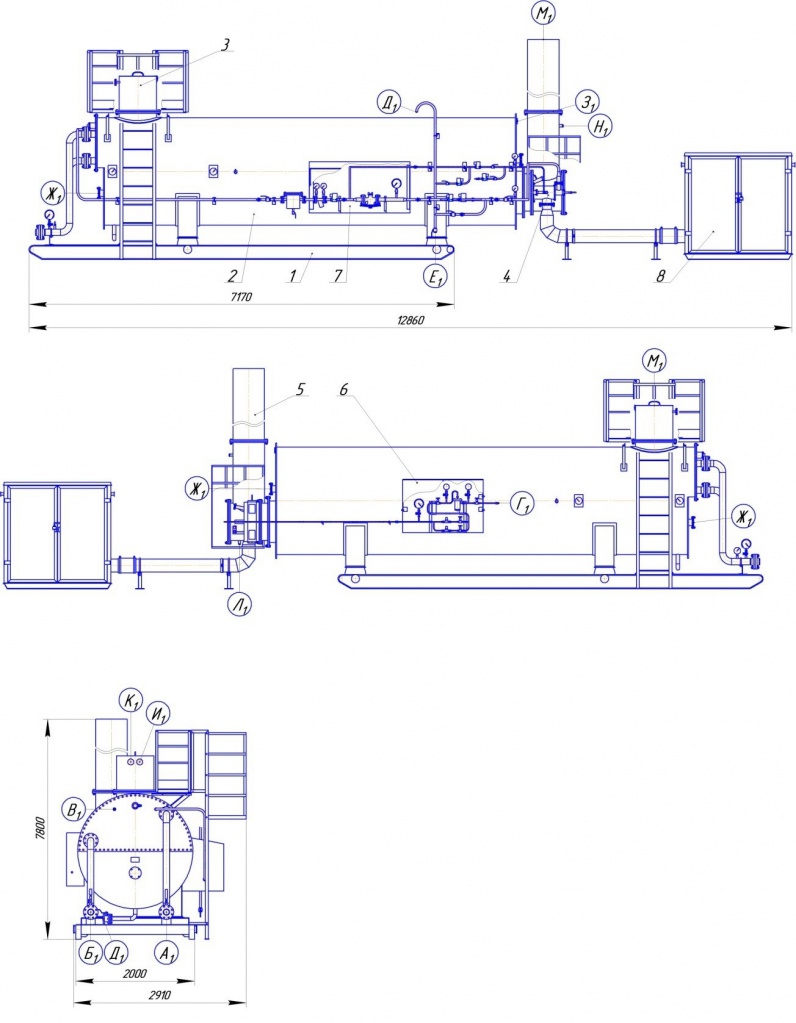

PP-0.63AMZhG basic assembly units:

1) skid frame;

2) furnace shell;

3) expansion tank;

4) burner device;

5) fume stack;

6) liquid fuel treating cabinet;

7) gaseous fuel treating cabinet;

8) ventilation set block

PP-0.63AMZHG general drawing.

|

Chokes and Flanges Table |

||||

|

Ref |

Designation |

Qty |

Nominal |

DN, mm |

|

A1 |

Oil inlet |

1 |

6.3 (63) |

100 |

|

Б1 |

Oil outlet |

1 |

6.3 (63) |

100 |

|

В1 |

Fuel gas inlet |

1 |

1.6 (16) |

25 |

|

Г1 |

Liquid fuel inlet |

1 |

4.0 (40) |

10 |

|

Д1 |

Tank drainage |

1 |

1.6 (16) |

50 |

|

Ж1 |

Assembly choke |

1 |

0.1 (1.0) |

100 |

|

З1 |

Observation choke |

1 |

0.1 (1.0) |

80 |

|

И1 |

Heat carrier supply |

1 |

1 (10) |

20 |

|

К1 |

Heat carrier discharge |

1 |

1 (10) |

20 |

|

Л1 |

Drainage of furnace condensate |

1 |

0.1 (1.0) |

15 |

|

М1 |

Fume gas outlet |

1 |

0.1 (1.0) |

500 |

|

Н1 |

Sampling choke with gas analyzer |

1 |

0.1 (1.0) |

20 |

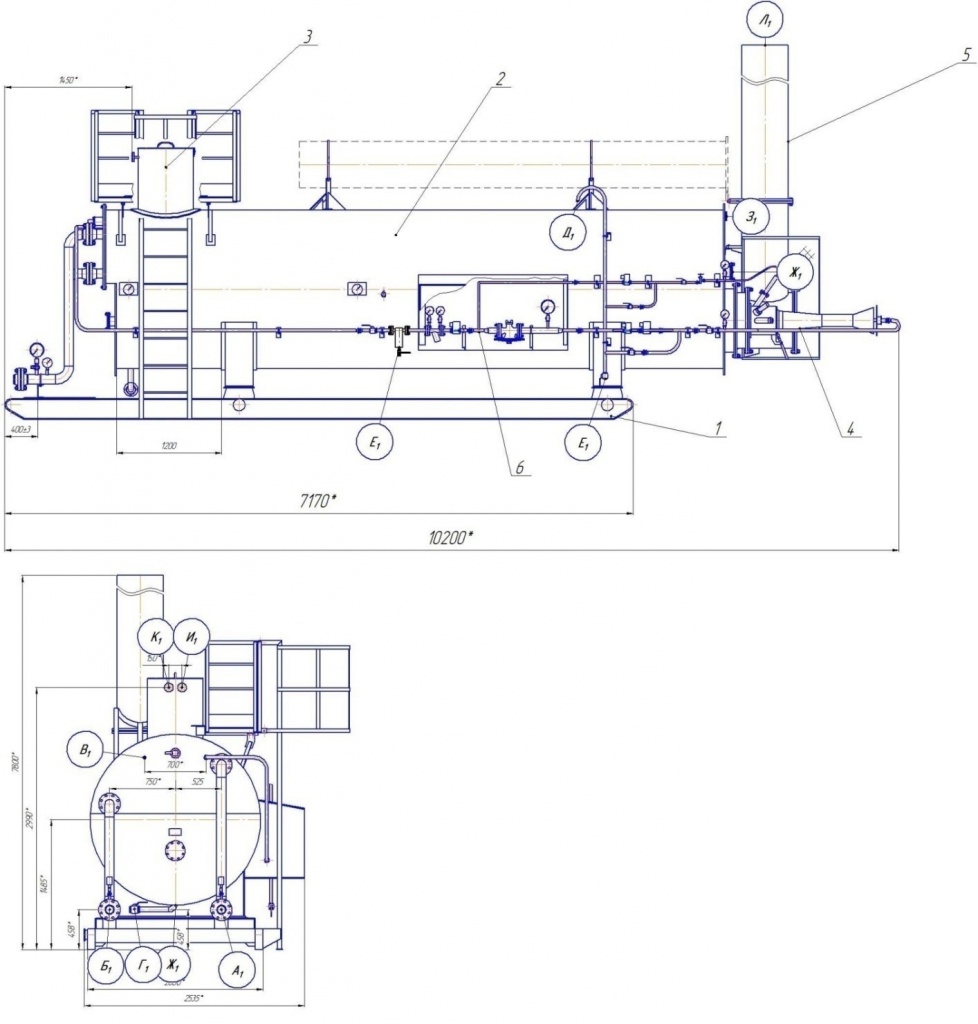

1) skid frame;

2) furnace shell;

3) expansion tank;

4) burner device;

5) fume stack;

6) fuel treating block

PP-0.63AS general drawing.

|

Chokes and Flanges Table |

||||

|

Ref |

Designation |

Qty |

Nominal |

DN, mm |

|

A1 |

Oil inlet |

1 |

6.3 (63) |

100 |

|

Б1 |

Oil outlet |

1 |

6.3 (63) |

100 |

|

В1 |

Fuel gas inlet |

1 |

1.6 (16) |

25 |

|

Г1 |

Tank drainage |

1 |

1.6 (16) |

50 |

|

Д1 |

Fuel gas purge to candle |

1 |

1.6 (16) |

25 |

|

Е1 |

Drainage of fuel gas lines |

2 |

1.6 (16) |

25 |

|

Ж1 |

Assembly choke |

3 |

0.1 (1.0) |

100 |

|

З1 |

Observation choke |

1 |

0.1 (1.0) |

80 |

|

И1 |

Heat carrier supply |

1 |

1 (10) |

20 |

|

К1 |

Heat carrier excess discharge |

1 |

1 (10) |

20 |

|

Л1 |

Fume gas outlet |

1 |

0.1 (1.0) |

500 |